Minimum quantity manager

Minimum quantity manager

Minimum quantity manager

SPM documentation of version 4.7.0.0 - April 18th 2011 – Written by Rémi Equoy

Introduction

This tool enables to know the volume of PN ordered for a given period.

The suggested minimum quantity is obtained by calculating the flow of orders and the last vendor's lead time.

To evaluate a quantity to order, use Re-provisioning forecast tool.

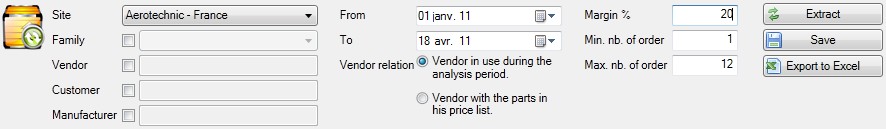

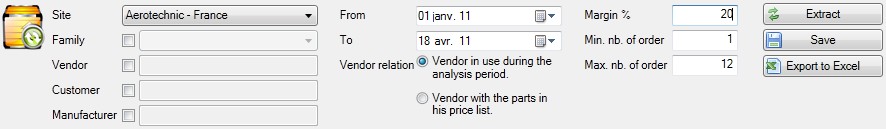

Input parameters

The followings inputs parameters define the request :

- Site

- Family - This filter enables to extract parts from the selected family.

- Vendor - This filter enables to extract parts already ordered to this vendor OR parts proposed by a vendor (see Vendor relation)

- Customer - This filter enables to extract only parts sent to one customer.

- Manufacturer - This filter enables to extract only parts from the concerning manufacturer.

- From and To define the period

- Margin % : Define the margin to computed the suggested minimum quantity

- Min. nb. of order: dynamic filter to define the minimum number of order (1 by default)

- Max. nb. of order: dynamic filter to define the maximum number of order (max by default)

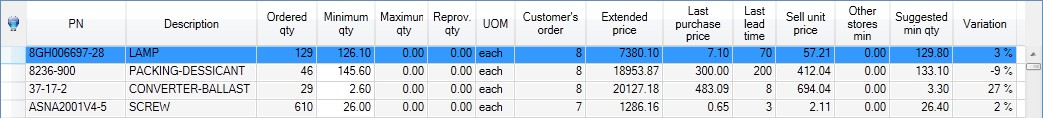

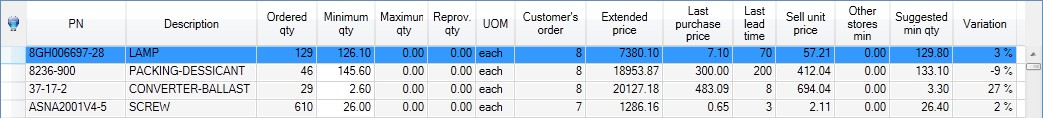

Result list

Once the inputs parameters are well defined, push the Extract button to obtain the restocking list. The followings columns appears :

- PN - Part Number - This column describe the part.

- Ordered qty - Quantity of Part Number order by the customer

- Min. qty - Minimum quantity of the default store.

- Max. qty - Maximum quantity of the default store

- Reprov. qty - Re-provisioning quantity of the default store

- UOM - Unit Of Measure

- Customer's orders - Number of customer's orders observed during the period. This column is very usefully to estimate the reliability of an restocking order.

- Sell unit Price - This value is computed with the average sell price (given in the PN's base unit of measure, not the sell unit). always in €.

- Extended price - This value represent the sum of all sells occurred during the observation period.

- Last vendor - Code and name of the last vendor where parts have been ordered.

- Last purchase price - Price of the parts with the price list of the last vendor where parts have been ordered.

- Last lead time - Lead time to receive parts fro the latest vendor.

- Last vendor - Code and name of the latest vendor.

- Other stores min - Sum of all minimum quantity of all stores included into the site excluding default store.

- Suggested min quantity: This value is [Margin] x [ordered qty] x [Latest lead time] / [Nb of days into the period] - [other min]

- Variation: Express the difference between the suggested minimum quantity and minimum quantity in progress.

See also - Re-provisioning forecast - Restocking worksheet -

See also - Re-provisioning forecast - Restocking worksheet -

Created with the Freeware Edition of HelpNDoc: Easily create Help documents

Minimum quantity manager

Minimum quantity manager Minimum quantity manager

Minimum quantity manager

See also - Re-provisioning forecast - Restocking worksheet -

See also - Re-provisioning forecast - Restocking worksheet -