Re-provisioning

Re-provisioning forecast

Re-provisioning forecast

SPM documentation of version 2.1.69.4 - July 9th 2009 – Written by Rémi Equoy

Introduction

Re-provisioning forecast tool enables user to obtain a list of item he probably should order to forecast a next period of work.

The result is obtained by comparing the available quantity and the number of items expedited thought a given period.

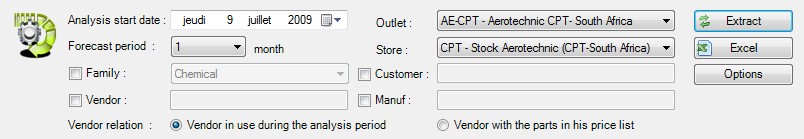

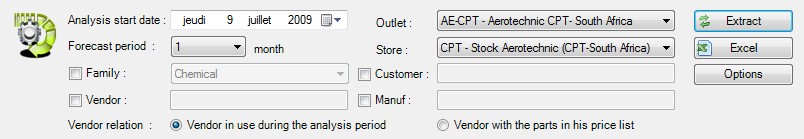

Input parameters

The followings inputs parameters define the request :

- Analysis start date - This date define the start of the observation period. The observation period ends at the moment (day) of the request. During this period, all parts delivered will be counted.

- Forecast period - 1 to 12 month - This value enables to define the period we want to order and is used in the compute process to evaluate the suggested purchase quantity.

- Outlet - The outlet combo box define the store list available.

- Store - The Store on which the restocking will be computed. Only parts delivered from this store will be used in the restocking process.

- Family - This filter enables to extract parts from the selected family.

- Vendor - This filter enables to extract parts already ordered to this vendor OR parts proposed by a vendor (see Vendor relation)

- Customer - This filter enables to extract only parts sent to one customer.

- Manuf. - This filter enables to extract only parts from the concerning manufacturer.

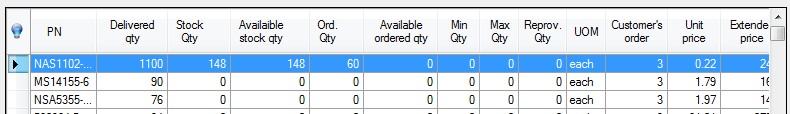

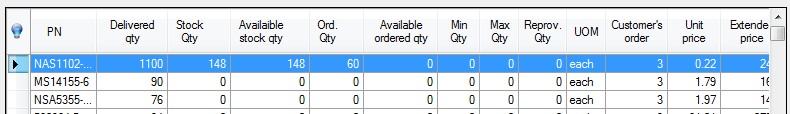

Result list

Once the inputs parameters are well defined, push the Extract button to obtain the restocking list. The followings columns appears :

- PN - Part Number - This column describe the part.

- Delivered quantity - Number of parts (in the base UOM of the PN) delivered during the observation period.

- Stock quantity - Quantity of parts present in the stock at the moment of the request.

- Available stock quantity - Quantity of parts present in the stock and not booked at the moment of the request.

- Available ordered quantity - Quantity of part present in all purchase order (in in progress status or more) and not booked at the moment of the request for customer order.

- Total available quantity - Quantity of available parts. Equal the sum of available qty plys available pre ordered qty plus available ordered qty.

- Min. quantity - When the stock value is under this quantity, the line will be appears automatically in this restocking list. This value is user defined in the PN form, Stores tab.

- Max. quantity - This value is user defined in the PN form, Stores tab.

- Reprov. qty - Re-provisioning quantity

- UOM - Unit Of Measure

- Customer's orders - Number of customer's orders observed during the period. This column is very usefully to estimate the reliability of an restocking order.

- Sell unit Price - This value is computed with the average sell price (given in the PN's base unit of measure, not the sell unit). always in €.

- Extended price - This value represent the sum of all sells occurred during the observation period.

- Suggested purchase quantity - This value is a forecast to order quantity.

- Last vendor - Code and name of the last vendor where parts have been ordered.

- Last purchase price - Price of the parts with the price list of the last vendor where parts have been ordered.

- Last lead time - Lead time to receive parts fro the last vendor.

- Priority - This priority is computed with the option values defined in the option dialog box (see below)

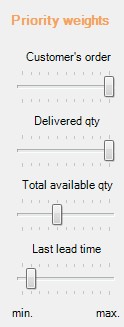

Options

By defaults options are defined but you can change the option to re compute the priority column. To use correctly this feature, ensure the sort is set in this column.

Four slides enables you to modify the weight of the calculation :

|

- Customer's order - Number of customer's orders observed during the period.

- Delivered quantity - Number of parts (in the base UOM of the PN) delivered during the observation period.

- Total available quantity - Quantity of available parts.

- Last lead time - Lead time to receive parts fro the last vendor.

|

Tool

By right clicking a contextual menu enables you to open the select PN or to hide the line. Once hided, you have to extract data to show all lines.

See also - Minimum quantity manager - Restocking worksheet -

See also - Minimum quantity manager - Restocking worksheet -

Created with the Freeware Edition of HelpNDoc: Easily create PDF Help documents

Re-provisioning forecast

Re-provisioning forecast Re-provisioning forecast

Re-provisioning forecast

See also - Minimum quantity manager - Restocking worksheet -

See also - Minimum quantity manager - Restocking worksheet -